Deconstruction and Reconstruction of RATP's Saint-Fargeau Train Maintenance Workshop in Paris

- 15 mars 2025

- 2 min de lecture

Dernière mise à jour : 17 juil. 2025

Background and Context

The Régie Autonome des Transports Parisiens (RATP) is the French state-owned public transport operator founded in 1949, headquartered in Paris, and today ranks as the world’s third-largest urban transport system, with around 64,000 employees managing metro, tram, RER, and bus services across Île‑de‑France and beyond.

Among its historic facilities, the Saint‑Fargeau train maintenance workshop, opened in December 1904, is a key site for the upkeep and overhaul of rolling stock on Paris Métro Lines 3, 3bis, and 7bis. Today, Saint‑Fargeau operates under RATP Infrastructures and is scheduled for modernization to support the new MF19 fleet, continuing its vital role in ensuring reliable metro operations in the Paris region.

Between 2025 and 2035, eight metro lines will welcome new, ultramodern trains. Called MF19, these trains will be equipped with interconnections and refrigerated roof ventilation to improve passenger comfort. The industrial infrastructure must therefore be adapted to the maintenance of this new rolling stock.

To prepare for the arrival of the new trains on lines 3, 3 bis, and 7 bis, the Saint-Fargeau Train Maintenance Workshop (AMT) will be completely modernized and restructured. Located on Rue Belgrand in the 20th arrondissement of Paris, it occupies part of a 1.5-hectare site owned by RATP.

What We've Done

Since 2023, Neo-Eco has been supporting RATP Infrastructures, the developer and project manager, as the Circular Economy Project Manager. Furthermore, this project is one of the 4 demonstrator projects of the Circular Economy Roadmap adopted by the RATP at the end of 2022 and whose design Neo-Eco supported.

Mission 1 - Diagnostics

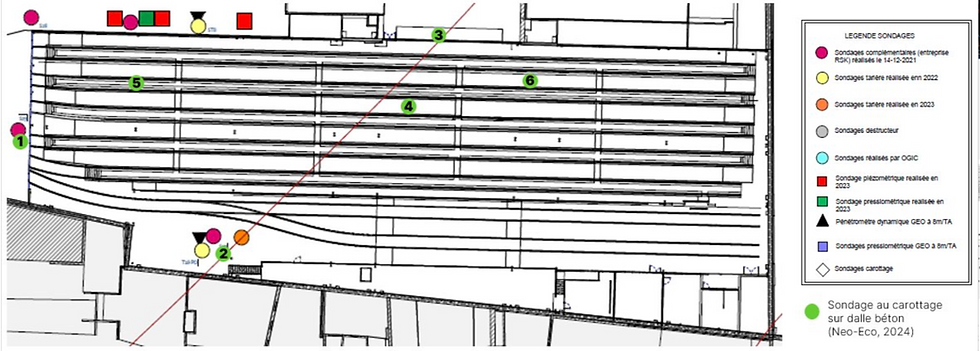

We carried out a detailed survey of materials and resources to understand what could be reused or recycled (PEMD diagnostic and resource assessment).

We supported the project team during early design stages to ensure circular economy principles were included from the start.

We took concrete samples and analyzed their quality to plan for potential reuse or recycling.

Mission 2 – Environmental project management assistance for cleaning/demolition work for the full project lifecycle

We are ensuring that environmental considerations and reuse opportunities are being built into the project during the detailed design phase (PRO phase).

We are helping to write the technical requirements for contractors, including sustainability and reuse criteria, for inclusion in tender documents and contracts.

We are overseeing the demolition and cleaning work to ensure it meets environmental and circular economy goals.

We are conducting a final review to confirm targets for waste reduction, recycling, and reuse have been achieved.

Mission 3 – Environmental project management assistance for reconstruction work for the full project lifecycle

We are including environmental and reuse strategies into the project during the detailed design of the new facility (PRO phase).

We are assisting in preparing technical documents and contracts to ensure construction aligns with circular economy practices.

We are monitoring the reconstruction work to verify that environmental commitments and reuse plans are followed.

We will complete a final evaluation to measure environmental outcomes and document lessons learned for future projects.

Outcomes

This project is ongoing. Come back soon for more details!