Case Study: Reducing Costs and CO2 Emissions for the Grand Paris Express’s 200km of New Metro Lines

- Sep 30, 2024

- 2 min read

Background and Context

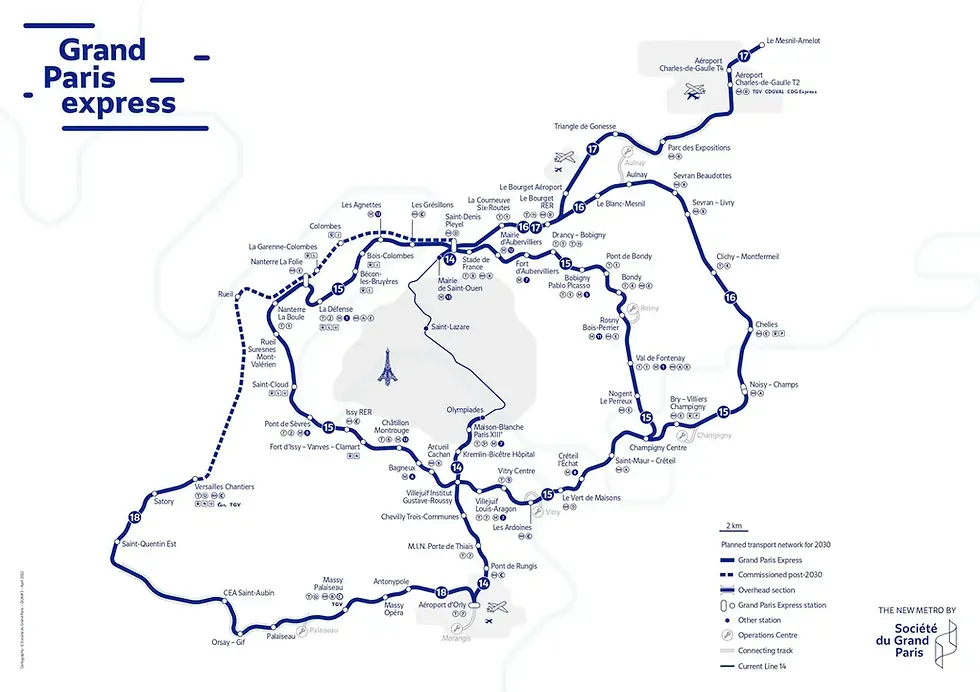

The Société des Grands Projets has been leading the charge on an ambitious plan to double the size of the Paris metro system by building 200km of new lines and dubbing it the Grand Paris Express.

However, this gargantuan project is forecasted to generate millions of tons of waste as the new tunnels are dug and buildings are demolished so that new metro stations can be built. It’s also expensive.

In order to combat costs, and to also respect the 2019 circular economy charter that the Metropole du Grand Paris developed and approved (with our help), Société du Grand Paris approached us for assistance.

What We Did

Plan Analysis & Site Visits

We began by analyzing the project plan to understand the full scope, including the volumes and characteristics of the forecasted waste flows, including everything from the dirt to be excavated from the tunnels and the buildings to be demolished so that new metro stations can be built. We then visited sites around the city to collect waste samples for testing.

Eco-Material Formulation

After understanding the physical and chemical characteristics of the project’s different streams of waste, we proceeded to develop eco-materials in our lab that could be reinjected back into the construction process. Because the project is forecasted to produce about 45M tons of excavated dirt, we focused on engineering highly valuable solutions around this particular waste stream.

Building Deconstructions

The project identified 21 structures that needed to be demolished so that supporting infrastructure and metro stations could be built. We developed and shared a methodology to intelligently deconstruct the buildings, recycling all their components into materials they could use in the construction of their new buildings.

Stakeholder Engagement

Any large infrastructure project like this requires the engagement of multiple stakeholders, spanning local and regional government, the private sector, the media, and residential communities. We liaised with many of these stakeholders to build consensus and successfully implement our proposed solutions.

Industrial Rollout

Converting 45M tons of excavated earth into eco-materials like low carbon cement requires skilled execution, and we have been providing this assistance to the Société du Grand Paris as their construction continues.

Outcomes

This project has led to several successful outcomes:

We saved the developers hundreds of thousands of euros in materials costs.

Over 100 local construction companies responded to our open call, expressing a desire to learn our techniques in creating eco-materials from construction and demolition waste so they could contribute to the massive project.

We developed over 80 eco-materials and products that could be created and re-used locally from the project's different types of waste.

We avoided the buildup of landfills and brought a record-setting level of sustainability to the infrastructure project.

.png)